During the past decades, the volume and the composition of the traffic also have changed, this change is reflected in the deterioration processes. In order to monitor these processes, we require a new type of equipment for measuring which performs cost-effective measurement in a short time, with the lowest possible disruption to the traffic. Recognizing this need, the Swedish Institute for Transport Sciences has developed a measuring system which has performed measurements in many countries of the world ever since to determine the condition of the pavement related to design and research work.

Reliable technology in a new coat

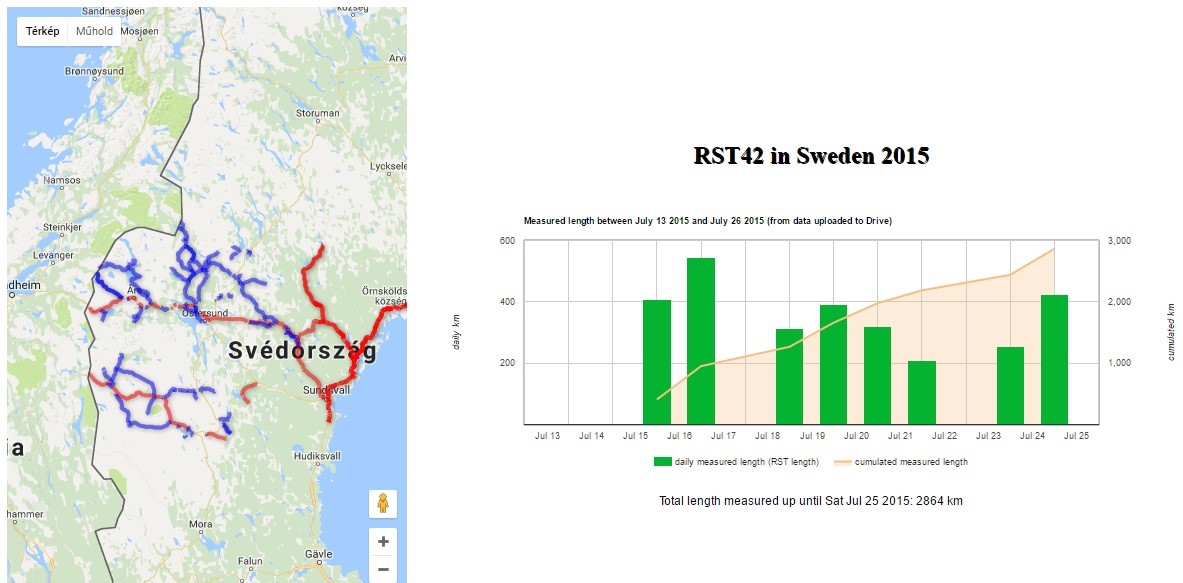

Having T7 Mérnökiroda Kft. and the Swedish RAMBOLL company cooperated, the LASER RST measurement device was placed on a new carrier vehicle, and as a result, it can measure road geometry and pavement condition without touching the road surface. Besides, the measurement is also regardless of the speed according to today’s standards. The LASER RST measurement system is placed on the front bar of a Mercedes Sprinter, on which laser cameras (19 pieces) and inertial sensors can be found. The system is able to provide measurement data from any types of roads which have a solid surface. Due to the diversity of the information supplied by the measuring system, it can be used for multiple purposes such as measurements to record condition, before-and-after tests of renovations, basic data for design and PMS systems as well.

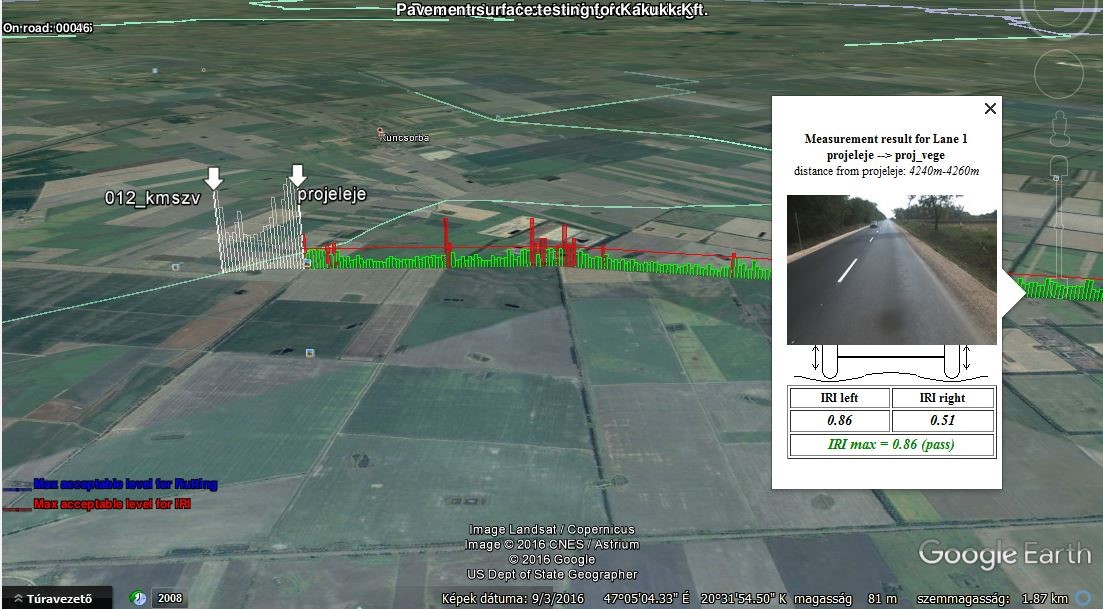

Examples of calculated parameters are:

- Road geometry, e.g. crossfall, hilliness and curvature

- Roughness along the road, e.g. longitudinal profile, IRI and straight edge

- Unevenness across the road, e.g. rut depth, risk of aquaplaning

- Road surface texture, e.g. MPD and RMS texture, and ravelling

- Images of the surface and the road surroundings

- Travelled distance

- Coordinates

The advantages of the system:

- It is considered a real-time data processing because the system determines the longitudial profile, tansverse profile, roughness, rut depth and the road geomety values with one measurement.

- It collects data using laser cameras and inertial sensors without touching the road surface.

- With the high-precision voltage pulse encoder, the distance can be measure accurately.

- The survey speed is the same as the traffic’s.

- Faulty data collection can be excluded with regular monitoring of the sensors and with calibration.

Data processing:

The experts of the T7 Mérnökiroda Kft. carry out the processing of data according to the demand of the costumer. Having the processing performed, the database of the results is transferred in a format requested by the customer.

The Laser RST meets the following standards:

- ASTM E950 (class 1): Measuring longitudinal profile.

- ASTM E1926: Computing IRI.

- EN 13036-6 (class 1): Road and airfield surface characteristics

- ISO 13473: characterization of pavement texture

- ISO 8608: Mechanical vibration, road surface profiles.